Surin Group is a leading manufacturer & supplier of auto and construction equipment components with “ISO 9001:2015, IATF 16949:2016, ISO 14001:2015, ISO 45001:2018, ISO 3834-2:2021” certification.

At Surin Group, we understand that quality is not just a goal, it’s a standard we uphold in everything we do. From our product to our customer support, quality is at the heart of our operations. Hers’s how we ensure excellence every step of the way: –

Rigorous Quality Control Processes

We have implemented stringent quality control measures throughout our production delivery process. Every product undergoes thorough testing and inspection to meet the highest standards before reaching our customers.

Skilled Team of Professionals

Our team comprises dedicated professionals who are experts in their respective fields. From product development to customer services, our employees are committed to delivering excellence and exceeding expectations.

Premium Materials and Technologies

We believe that quality starts with the right materials and technologies. That’s why we invest in top-of-the-line materials and cutting- edge technologies to ensure that our products are of the highest quality.

Customer Satisfaction Guarantee

Our commitment to quality doesn’t end with the sale. We strive for 100% customer satisfaction, and we go above and beyond to address any issues or concerns our customers may have. Your satisfaction is our priority.

Continuous Improvement

We are dedicated to continuous improvement and innovation. We regularly review and enhance our processes to adapt to changing market demands and deliver even better products to our customers.

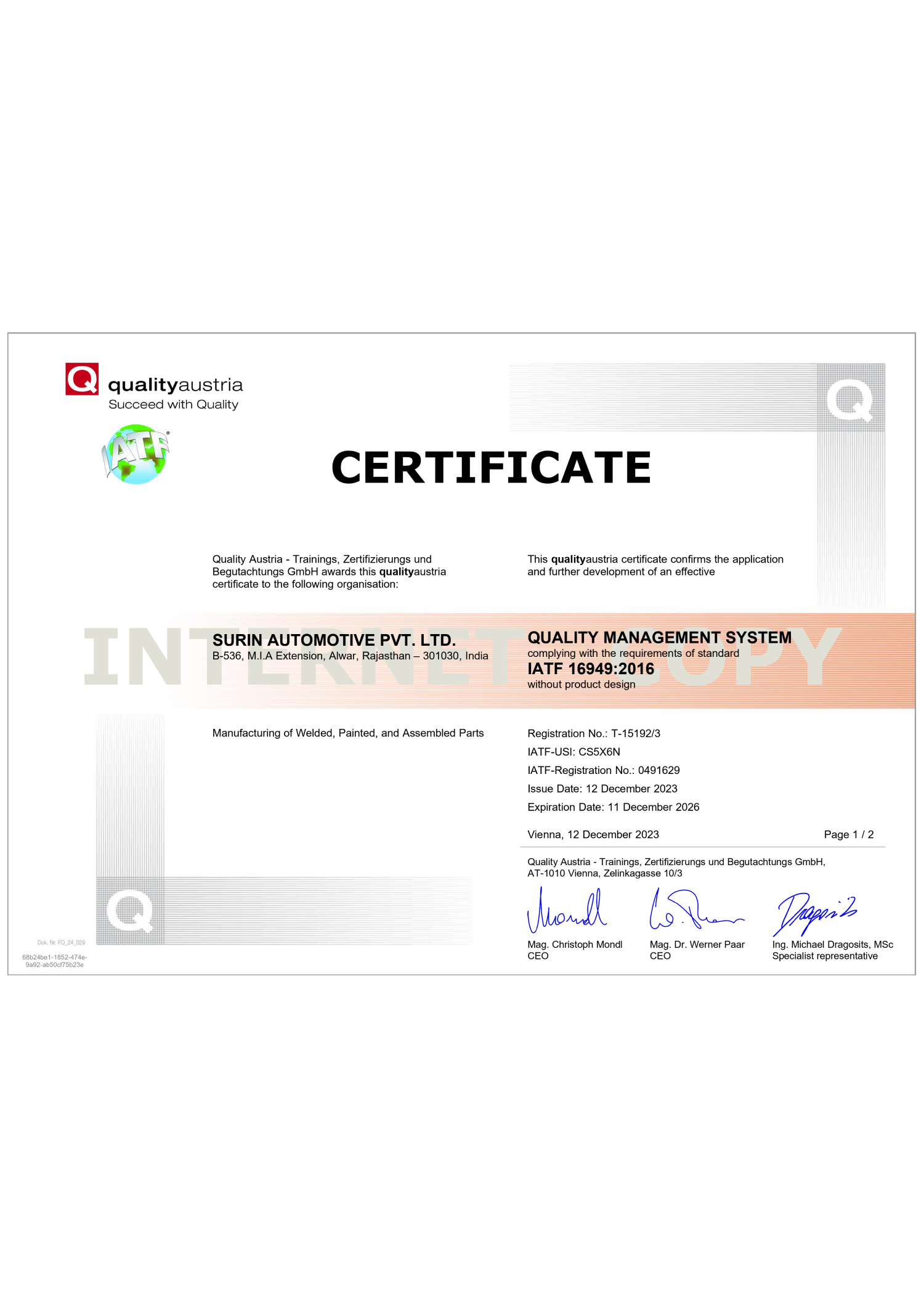

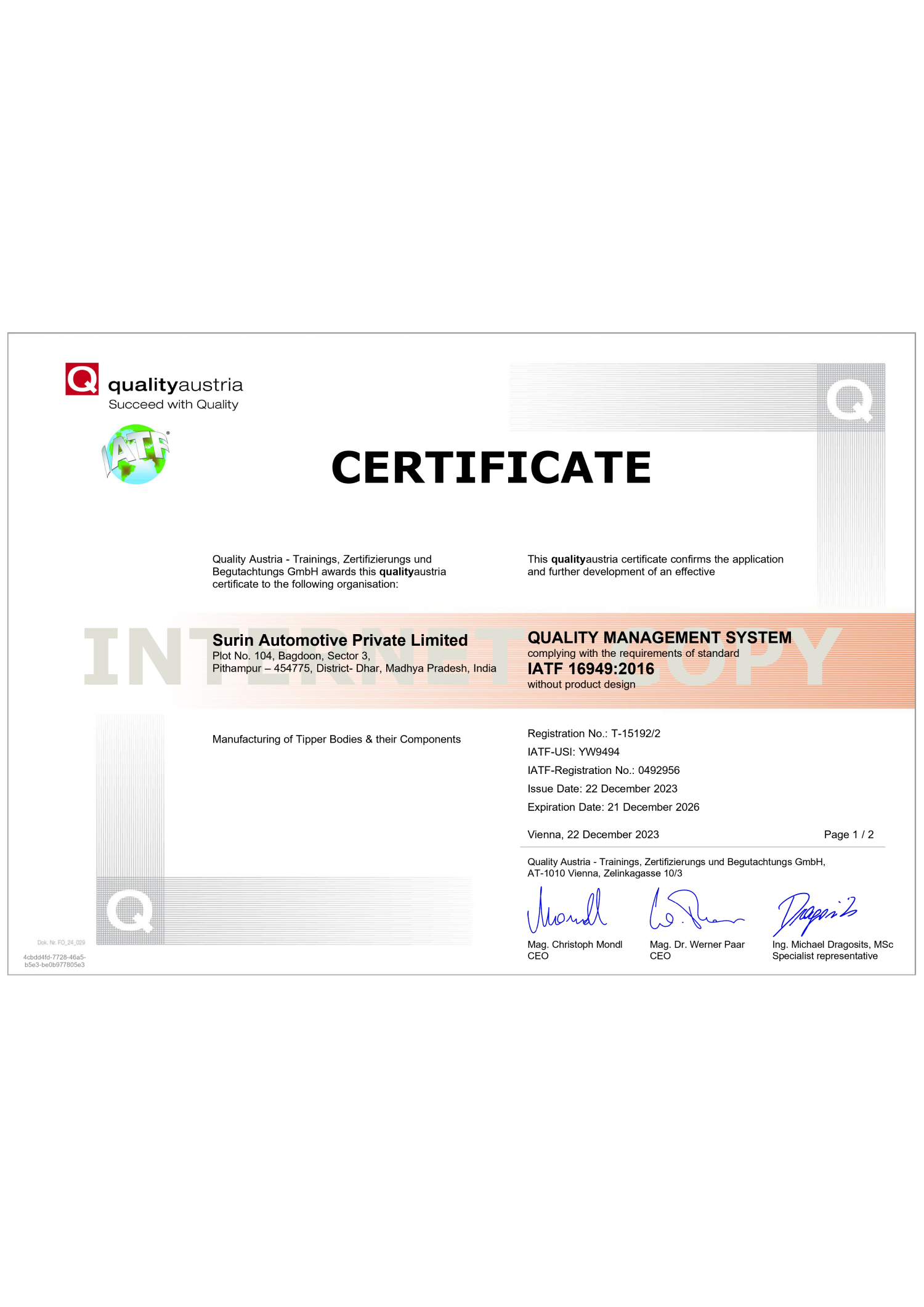

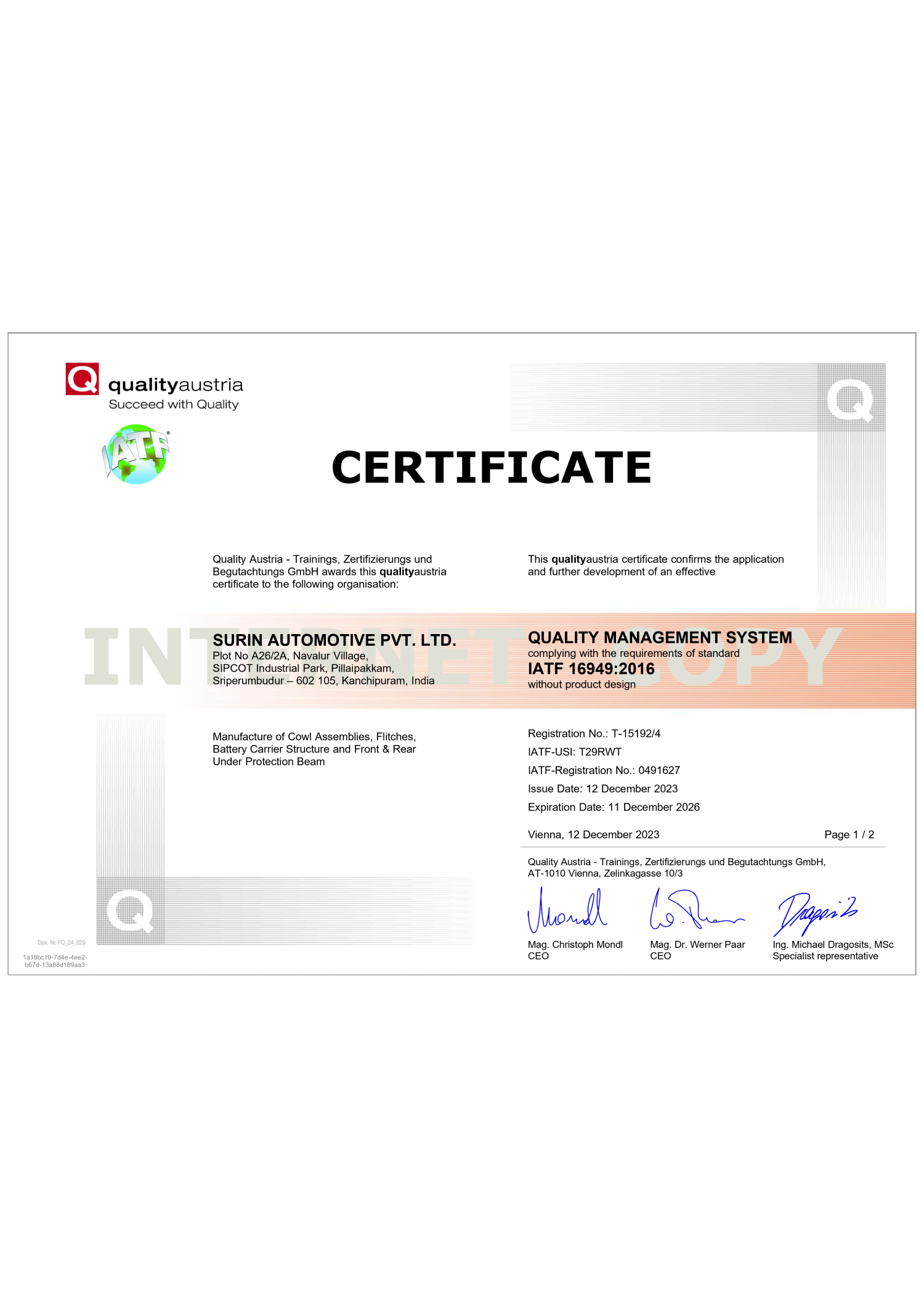

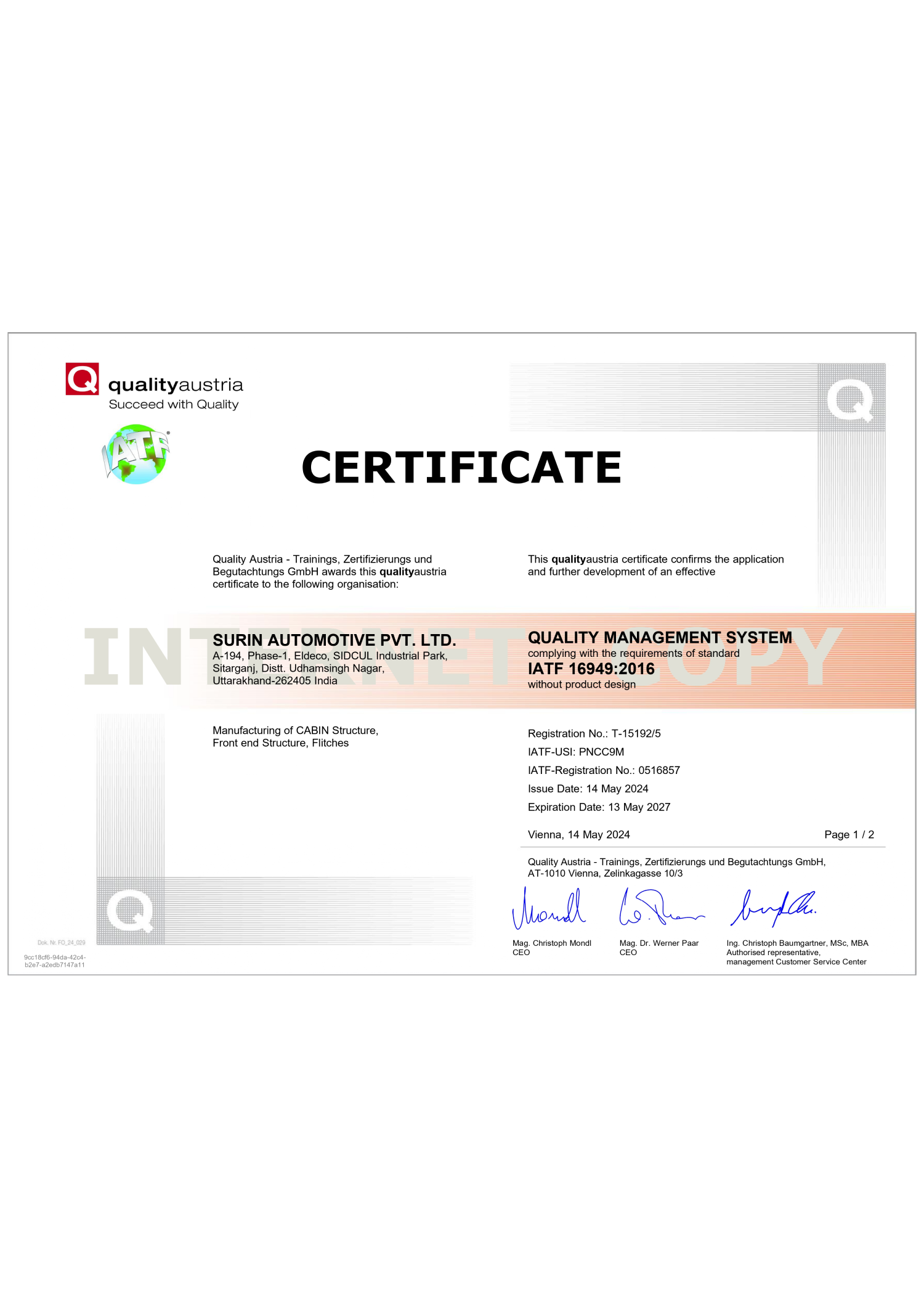

Industry certification and Accreditations

Surin Group is proud to hold industry certifications and accreditations that demonstrate our commitment to quality and excellence. These certifications serve as a testament to our dedication to upholding the highest standards in our industry.

Transparency and Accountability

We believe in transparency and accountability in everything we do.

In our relentless pursuit towards excellence, we at Surin Automotive have benchmarked various industries best practices and devised our unique operation excellence model Su-QuEST (Surin Quality Excellence Standard). This entails 5 levels of maturity for each of our manufacturing plant to qualify through a rigorous assessment process. Presently, our 3 plants have already achieved Su-QuEST Level-1 status. 2 plants of SAPL – Uttarakhand and SAPL – Alwar unit.

All our existing plants are commonly certified under corporate certification scheme, for Integrated Management System – IMS (ISO-9001:2015, ISO-14001:2015, ISO-45001:2018).

Besides, our following plants are certified for IATF 16949:2016, which supplies products to Commercial Vehicle segment customers : SAPL – Navallur, Chennai; SAPL – Pithampur, Indore; SAPL – Alwar, Rajasthan; SAPL unit 1&2 – Sitarganj, Uttarakhand.

Also, our following plants are certified for ISO-3834-2:2021 (Quality requirements for Fusion Welding) : SAPL – Pillaipakkam, Chennai; SAPL – Bambholi, Chakan, Pune; SAPL – Wasuli, Chakan, Pune; SAPL – Pithampur, Indore; SAPL unit 2– Sitarganj, Uttarakhand; SAPL – Peenya, Bengaluru.

Quality Instruments

-

HEXAGONAL PORTABLE CMM

Measuring Range : 2.5 m / 8.2 ft.

Volumetric Accuracy : ± 0.051 mm

Single Point Repeatability : 0.038 mm -

STEREO MICROSCOPE (Welding Penetration Equipment)

Specifications:

Eyepiece: Wide field eyepieces 10X (paired) fov 22mm

Magnification Range: 0.8X to 50X

Working Distance: 115mm -

PORTABLE LEEB HARDNESS TESTER

Make : TIME®5300 (TH110)

Measuring range : (170-960)HLD (17.9-69.5)HRC Base on Different probe

Hardness scale : HL, HB, HRB, HRC, HV, HS

Measuring direction : 360°

Tolerance : ±6HLD(when HLD=760±30) Base on Different probe

Repeatability : 6HLD(when HLD=760±30

-

WEIGHING MACHINE

Range

MAX : 210g

MIN :100mg -

WEIGHING MACHINE

Range :

MAX : 2KG

MIN :4 g -

Feeler gauge

Specifications:

Range : 0.05 TO 1mm -

TRY SQUARE

Specifications:

Range : 0-90 ° -

BORE GAUGES

Specifications:

Range :18-35mm

35-60mm

50-100mm -

PLUNGER TYPR GAUGE

Specifications:

Range :0-10 µm

0-600 µm -

DIAL GAUGE

Specifications:

Range :0-200 µm -

BEVEL PROTECTOR

Specifications:

Range :0-360 ° -

OVEN

Specifications:

Size:12x12x12

Volts: 240

Watts:1000

Max temp : 250 Degree -

RADIUS GAUGE

Specifications:

Range : 7.5-15mm

15.5-25.00mm -

V BLOCK

Specifications:

Range :150X75X100

100X100X95 -

RING GAUGE

Specifications:

Range :M5 TO M64 -

THREAD PLUG GAUGE

Specifications:

Range :M5 TO M64 -

MICROMETER

Specifications:

Range : 0-25mm, 25-50mm, 50-75mm, 75-100mm, 100-125mm, 125-150mm, 150-175mm, 175-200 mm -

VERNIER CALIPER

Specifications:

Range : 0-150mm, 0-300mm, 0-600mm -

HEIGHT GAUGE

Specifications:

Range: 0-600mm

Vernier Height Gauge List count=0.02

Digital list count=0.01 -

SURFACE TABLE

Specifications:

2000x1500mm, 900×750mm, 630×630mm, 1000×1000mm -

COATING THICKNESS GAUGE

-

SOUND METER

Features

Type of Product : Sound Level Meter

Range : 35-130 dB

Accuracy : ±1 dB

Microphone : ½ Inch Electret Condenser

-

GLOSS METER

Measurement range:

Brand : Matrix

Display: 4 Digits Backlit LCD

Accuracy: +-1.0GU

Range : 0.1-200 Gloss Units

Resolution : 0.1Gloss Units : GU

Measuring Angle: 20 Deg./60 Deg./85 Deg.

-

LUX METER

Specifications:

Range: 0 to 200000 LUX

Accuracy: ±5% of reading

Receiving light: Silicon of photo electricity diode

Power Source: 1×9.0V (6F22) -

PH METER

Specifications:

Range : 0-14pH -

TITRATION CHECKING EQUIPMENT

1.Conical flask

2.Pipette

3.Burette & burette stand -

ULTRASONIC FLAW DETECTOR

Application:

Flaw detection can be applied in almost any industry from composites and metals used in aerospace, to petrochemical oil and gas pipelines, storage tanks and power generation including nuclear power. The most common anomalies include cracks, voids and porosity in metals, ceramics and plastics in addition to delimitations and disbands in composites. -

ELECTRO MAGNETIC YOKE

Specifications:

Pole Distance 50 to 300 mm

Cord Length 2 meters Input Supply 220 VAC, 50Hz, 1 Phase (EF-2Y)

110 VAC, 50Hz, 1 Phase (EF-3Y) Max.

Current Drawn 2.5 Amp

Lifting Capacity at 100 mm pole spacing 5 Kg AC mode

(EF-2Y) 27 Kg DC Mode (EF-3Y) Yoke Weight 4 Kg Controls Solid State Control -

SUCTION PUMP

Specifications:

Vacuum/Pressure Pumps For flow rates of up to 37 L/min. -

SLIP GAUGE

Specifications:

1.005mm TO 100mm

-

POLISHING MACHINE

Specifications:

1/2HP high torque AC Drive motor

8″ disc diameter Standard .

-

Usages of Portable CMM:

- 2D Measurement

- Part to CAD comparison

- Part to Part comparison

- GD & T inspection

- Jigs & Fixture setup

-

MEASUREMENTS

1 Supports all weld quality parameters like depth/penetration, %penetration, leg lengths, throat lengths, root penetration etc.

2.Can measure length, area, angle, diameter, radius, circumference in addition to weld penetration measurement

3.Can set expected values and tolerances for each parameterREPORT

Reports in Excel or PDF format (Customizable format)

-

USES:

1 Conversion of common hardness scales (HL, HV, HB, HRC, HRB, and HS)

2)High accuracy and wide range options for testing(: including Steel and Cast steel, Forged Steel, Cold Work Tool Steel, Stainless Steel, Gary Cast Iron, Nodular Cast Iron, Cast Aluminium Alloys, Brass (Copper-zinc alloys), Bronze (copper-aluminium /copper-tin alloys), Wrought Copper Alloys)REPORT

Reports in Print (Customizable format)

-

Weighting Scales are used to measure the weight of an item

-

Weighting Scales are used to measure the weight of an item

-

USES:

A feeler gauge is a tool used to measure gap widths. Feeler gauges are mostly used in measurement to measure the clearance between two parts.

-

USES:

To check a surface’s straightness or correspondence to an adjacent surface and ‘square’ (a 90°, or right, angle).Try squares generally consist of two parts

-

USES:

They are typically used to measure deck clearances, straightness, lifter travel and other measurements that involve the distance between two surfaces or small amounts of component travel.

Roundness & Run out .

-

USES:

They are typically used to measure deck clearances, straightness, lifter travel and other measurements that involve the distance between two surfaces or small amounts of component travel.

Roundness & Run out .

-

USES:

a simple tool used to measure gap widths precision ground and lapped length measuring standard.

-

USES:

Measuring the angle between two face of component

-

APPLICATION

1.TO ANALYSISTHE VOLATILE, ASH, MOISTURE, ASH FUSION AND ELEMENTS IN COAL & COKE .2. TO SINTERING, MELTING METAL, CERAMIC, SILVER, GOLD AND OTHER MATERIALS.

3.FUSING GLASS, CREATING ENAMEL COATINGS, CERAMICS AND SOLDERING AND BRAZING ARTICLES. BAKE POTTERY AND PORCELAIN POTS, PLATES AND OTHER ARTICLES.

-

USES:

A radius gauge, also known as a fillet gauge, is a tool used to measure the radius of an object. Radius gauges require a bright light behind the object to be measured.

-

USES:

V blocks can be used to hold round parts horizontally

-

USES:

thread ring gauges are used to check the outside major diameter and pitch diameter limits on threaded parts

-

USES:

A thread gauge, also known as a screw gauge or pitch gauge, is used to measure the pitch or lead of a screw thread. Thread pitch gauges are used as a reference tool in determining the pitch of a thread that is on a screw or in a tapped hole.

-

USES:

A micrometer is a tool used for the precise measurement of very small objects. A micrometer can measure the length, thickness, external diameter.

-

USES:

A Vernier calliper is a precision instrument that measures Length, internal dimensions, outside dimensions, and depth.

-

USES:

A height gauge is a measuring device used for determining the height of objects, and for marking of items to be worked on.

-

USES:

The Surface plate is used as a measuring base or a datum surface for testing of flatness of surfaces.

Inspection & tooling setup.

-

USES:

Digital coating thickness gauges are ideal to measure coating thickness on metallic substrates. Electromagnetic induction is used for non-magnetic coatings on ferrous substrates such as steel, whilst the eddy current principle is used for non-conductive coatings on non-ferrous metal substrates

-

USES:

A sound level meter is a measuring instrument used to assess noise or sound levels by measuring sound pressure. Often referred to as a sound pressure level (SPL) meter, decibel (dB) meter, noise meter or noise dosimeter, a sound level meter uses a microphone to capture sound.

-

APPLICATION:

60° is referred to as the universal measurement angle and is the most commonly specified geometry in applications such as paints, coatings, plastics, automotive interiors and general manufacturing. It can be used as a basic gloss assessment for any surface20° is the angle selected for high gloss applications such as paints and coatings, polished metals as it gives an improved resolution for high gloss finishes. It is also more sensitive to haze effects that affect the appearance of a surface

85° is the recommended angle for low gloss finishes as it offers improved resolution of low gloss. This angle is recommended for surfaces which measure less than 10 GU when measured at 60º.

-

Application:

Lux is a measurement of the overall intensity of light within an environment for any given area or distance from the source or lux is the amount of light in an environments perceived by the human eye

-

Application:

PH meter, electric device used to measure hydrogen-ion activity (acidity or alkalinity) in solution. Fundamentally, a pH meter consists of a voltmeter attached to a pH-responsive electrode and a reference (unvarying) electrode

-

TEST:-

1.Degresing

2.Water Rinse

3.Phosphating ( Total Acidity)

4.Phosphating (Free Acidity)

5.Phosphating (Accelerator content)

6.Surface conditioning

7.Total acidity of water rinses after phosphate stage.

-

Specifications:

High end ultrasonic flaw detector

Ideal foe thickness survey

Test range from 205mm to 10 meters

Measurement Resolution of 0.01 mm

RF Waveform

For oxide scale thickness measurement

Encoded B-scan

Colour c ode C-scan

-

Magnetic particle Inspection (MPI) is a non-destructive testing (NDT) process for detecting surface and shallow subsurface discontinuities in ferromagnetic materials such as iron, nickel, cobalt, and some of their alloys.

-

Specifications:

Vacuum/Pressure Pumps For flow rates of up to 37 L/min.

These High Output Pumps feature a piston-driven design for greater power. As Chemical Duty Pumps, they have a chemically-resistant head and diaphragm for use with corrosive chemicals and solvents.

Vacuum/Pressure Pump (115V)Application:

Vacuum pump mechanism is used to remove air or any gas particles from the container that creates vacuum in the vessel.

-

USES:

They are used as a reference for the calibration of measuring equipment used in machine shops, such as micrometers, sine bars, callipers, and dial indicators (when used in an inspection role). Gauge blocks are the main means of length standardization used by industry.

-

Specifications:

1/2HP high torque AC Drive motor

8″ disc diameter Standard .

Many discs can be used

Thyristor controlled speed controller

Digital speed indicator – 1500 rpmApplication:

Disc Polishing Machines are finely polished to ensure smooth, scratch free and mirror like appearance that enable accurate metallographic interpretation. Polishing is the final stage in producing a surface that is flat, smooth, scratch-free and mirror like in appearance. Such a surface is necessary for subsequent accurate metallographic interpretation, both qualitative & quantitative.

OUR QUALITY POLICY

The Quality Policy of Surin Automotive Private Limited is to understand the customers, anticipate customer needs and satisfy them by providing timely supply of superior products and improve continually through innovations, and an established quality management system.

AWARDS

Discover our journey of excellence, recognized through numerous awards that highlight our commitment to quality, innovation and leadership.

CLIENTELE

Surin Automotive Pvt Ltd has a Diverse List of Clients across 5 Segments and also is exporting to leading OEM’s in Europe and America.

LET’S TALK

Lorem ipsum dolor sit amet, consectetur adipiscing elit. Nam ac nunc id massa ullamcorper egestas at pellentesque lorem. Quisque quis efficitur felis, at porttitor ante.

6A/6C, Peenya Industrial Area, Phase-1, BANGALORE 560 058

+91 80 40078158

contactus@surinauto.com